Welcome: Shenzhen Limei Technology Co., Ltd

Email: szlimei@tddfdd.com

- TOP

- 13025463935

- Online

- WhatsApp code

Producing a 4G Wi-Fi CPE router involves several stages, from design and development to manufacturing and testing. Here's a step-by-step guide on how we produce our 4G Wi-Fi CPE routers:

1. 1. Research and Design Team

j

· Conduct market research to understand customer needs and competitors' offerings.

· Define the specifications and features of the router, such as supported 4G bands, Wi-Fi standards, number of ports, and security protocols.

. Create a detailed product design, including the circuit diagram, PCB layout, and antenna placement.

2. Component Procurement

Our factory procures all the necessary components required for the production of the 4G Wi-Fi CPE routers. These components include the circuit boards, antennas, connectors, processors, memory chips, power supplies, and other electronic parts.

3. PCB Assembly

The first step is to assemble the Printed Circuit Board (PCB). Surface Mount Technology (SMT) machines are used to precisely place the electronic components onto the PCB. This process involves soldering the components onto the board using automated equipment.

4. Firmware Installation

Once the PCB are assembled, the firmware are installed. The firmware is the software that controls the operation of the routers. It includes the necessary drivers, protocols, and configurations for the 4G modem, Wi-Fi module, and other functionalities of the routers.

5. Testing and Quality Control

After the firmware installation, each router undergoes rigorous testing to ensure its functionality and performance. Various tests are conducted, including connectivity tests, signal strength tests, data transfer tests, and compatibility tests with different networks and devices. Quality control measures are implemented to identify and rectify any defects or issues.

6. Enclosure Manufacturing

Meanwhile, the enclosure or housing of the router’s are manufactured. This involves plastic molding or sheet metal fabrication, depending on the design. The enclosure provides protection and aesthetic appeal to the routers.

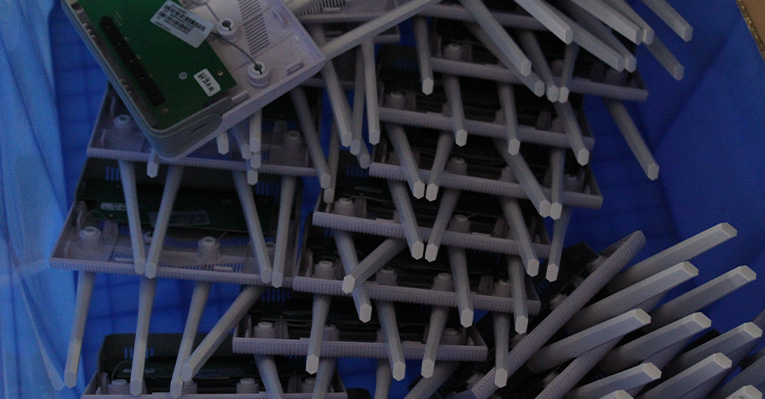

7. Assembly

The assembled PCB is integrated into the enclosure. The necessary connectors, ports, and buttons are attached to the enclosure. The antennas are also installed in their designated positions.

8. Final Testing

The fully assembled routers undergoes another round of testing to ensure that all components are properly integrated, and the routers functions as intended. This includes verifying the Wi-Fi signal strength, network connectivity, and other features.

9. Packaging

Once the routers has passed all tests, they are packaged for shipment. The packaging typically includes a box, user manual, power adapter, cables, and any other accessories.

10. Shipment

The packaged routers are prepared for shipment, which involves labeling, addressing, and arranging logistics for distribution to retailers, wholesalers, or directly our customers.

11. Quality Assurance

Throughout the production process, quality assurance measures are in place to ensure that our routers meet the required standards. This includes regular inspections, audits, and adherence to industry regulations.

Contact: Sorho

Phone: +8613025463935

Email: szlimei@tddfdd.com

Add: 1006, 10th Floor, Shajing Yunhua Times Building, Shenzhen, Guangdong, China